NOTE: R Values are related to HEAT absorbing materials like fibreglass (i.e. a Heat Sponge). R Values measure thermal storage or the storage of heat, calculate approximately how long it will take the heat absorbing material to reach saturation and thus are thickness dependent. The MINIMUM thickness required to calculate an R Value is one inch (1″) thick.

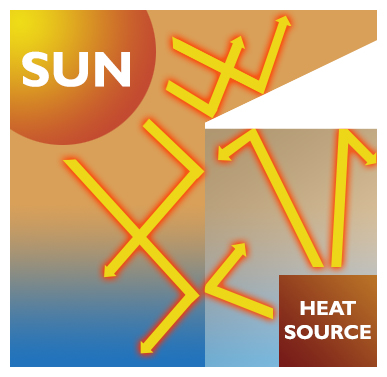

Technical Ceramics are NOT Thermal Absorbants but in fact are Thermal Barriers. They are HEAT blocking materials (i.e. a Heat Dam) and HEAT repelling materials (i.e. a Heat Shield) and therefore reduce thermal transfer i.e. insulate by offering different thermal benefits and may or may not be thickness dependent.

Here is a link to some excerpts from this arm’s length third party ISBU ASSOCIATION REPORT ON CERAMIC COATINGS which contains some excellent information on this technology and is well worth the read.

The question is, which type of insulation will provide the customer with the best THERMAL BENEFIT?

A Heat Shield, a Heat Dam, a Heat Sponge or a combination of materials? i.e. A Hybrid Insulation System. See below for more information on Hybrid Insulation Systems.

First of all, it is sometimes suggested that all Ceramic Coatings are the same. This is not true. That’s like saying all heat absorbing “air trapper” type of insulations are the same which is also not true. Fiberglass (approximately R3 per inch) is certainly not the same as Closed Cell Foam (approximately R6 per inch). First and foremost it should be understood that all ceramic coatings are not the same and are not created equal. Also there are substantial differences between a reflective paint which only addresses Visual Light (short wave) and a thermal barrier coating which addresses UV, Visual Light (short wave) and IR (long wave) with the primary difference being unlike a reflective paint, a Ceramic Coating still continues to work even after it gets dirty.

Even within our own family of Ceramic Coatings we have different coatings that contain different ceramics in different amounts and are engineered to perform different functions.

For example:

HPC® COATING Ceramic Insulation Coating contains seven different ceramics, weighs five (5) pounds per gallon and is Engineered to Block Heat and as per its Certifications references ISO8302 \ ASTM C-177 and has thermal conductivity of 0.063 W/mK and is engineered to stop thermal transfer via conduction. i.e. A one inch thickness (the minimum thickness required to calculate an R-Value) reduces 482°C \ 900°F down to 61°C \ 142°F which exceeds the Canadian standard of 70°C \ 158°F and is virtually compliant with the OSHA standard of 140°F \ 60°C. The dead air space contained within the ceramic Cenospheres also provides some thermal storage.

HPC® COATING Ceramic Insulation Coating contains seven different ceramics, weighs five (5) pounds per gallon and is Engineered to Block Heat and as per its Certifications references ISO8302 \ ASTM C-177 and has thermal conductivity of 0.063 W/mK and is engineered to stop thermal transfer via conduction. i.e. A one inch thickness (the minimum thickness required to calculate an R-Value) reduces 482°C \ 900°F down to 61°C \ 142°F which exceeds the Canadian standard of 70°C \ 158°F and is virtually compliant with the OSHA standard of 140°F \ 60°C. The dead air space contained within the ceramic Cenospheres also provides some thermal storage.

Ceramic Thermal Barrier Coatings contain four different ceramics, weigh twelve (12) pounds per gallon and are Engineered to Repel Heat. This reduces the amount of heat available to transfer by deflecting, repelling and emitting thermal absorptance or the amount of heat being absorbed and thus helping to keep heat in or out. These coatings are a tremendous benefit in mitigating the increasing heat of the documented Urban Heat Island Effect. Ceramic Thermal Barrier Coatings reduce HEAT LOAD by 90% – 95%!!! BEAT THE HEAT with a HEAT SHIELD!!!

Further information is available at:

Government of Canada Urban Heat Islands

Concordia University Cool Roofs Savings and Penalties in Cold Climates

Berkeley Lab’s Heat Island Group.

Both are Ceramic Coatings but are engineered differently to address different modes of thermal transfer.

They are sometimes used together in a HYBRID INSULATION SYSTEM as in the case of the COLD CLIMATE CONTAINER INSULATION – keeping a shipping container home warm at –40 C in Quebec, Canada. See below for further information on Hybrid Insulation Systems.

All of these products reduce CUI (Corrosion Under Insulation) and provide CI (Continuous Insulation) and thus eliminate thermal bridging.

|

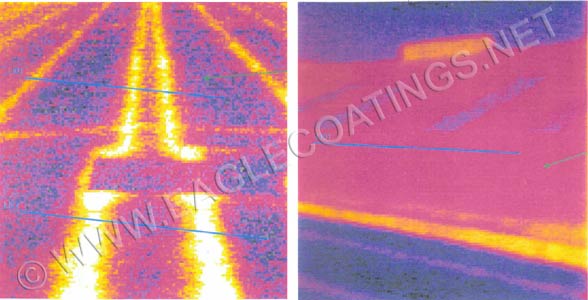

Uncoated roof insulated with fiberglass |

Roof with no fiberglass but insulated on the exterior only with a Ceramic Thermal Barrier Coating but still keeping heat in. |

Which would you prefer?

NOTE: In the application shown above on the right hand side, a Ceramic Thermal Barrier Coating was applied to the exterior only and the heat source was coming from the interior side. Consequently there was 100% absorptance of the heat into the interior side of the metal roof. That 100% absorptance then transferred through the metal roof via conduction and consequently only the 2 non conductive ceramics contained in Ceramic Thermal Barrier Coating were in effect. The 2 reflective ceramics were not being utilized and therefore a Ceramic Thermal Barrier Coating in this orientation only provides half the thermal benefit.

If a Ceramic Thermal Barrier Coating had been applied to the interior side and thus facing the heat source, all four ceramics would have been in effect and the full thermal benefit would have been realized.

One of the basis of this technology is to reduce heat loss or heat gain by reducing the amount of heat being absorbed by the surface and thereby reducing the amount of heat, sound and moisture available to transfer. This is accomplished by deflecting, repelling and emitting heat, sound and moisture.

SUPER THERM® Ceramic Thermal Barrier Coating is Engineered to Repel Heat by deflecting, repelling and emitting thermal absorptance which reduces the amount of heat being absorbed by approximately 90% on an interior application and by better than 95% on an exterior application. We believe this provides a significant thermal benefit. As noted by a PhD in Fluid Mechanics, on exterior applications “SuperTherm® is deflecting better than 95% of the heat to begin with therefore debating the remaining 5% is trivial.”.

This was validated by the first certified thermal test conducted for SuperTherm® being ASTM E1269 Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry in conjunction with ASTM E1461-92 Standard Test Method for Thermal Diffusivity of Solids by the Flash Method.

This was the certified ASTM testing recommended by the thermal laboratory located at Purdue University as it measures the thermal absorptance of the coating independent of the substrate to which it is applied.

This certified ASTM testing, documents the fact that SuperTherm® reduced Btu's absorbed from over 350+ Btu's per hr\ft2\F on a bare metal substrate (Table 4) down to 4 Btu's absorbed per hr\ft2\F on the metal substrate coated with SuperTherm® (Table 5).

Table 4 is the Thermal Conductivity calculations of the metal plate. Specific point of reference is at 100C \ 212 F there are 367.20 Btu’s per hr\ft2\F absorbed and conducted through the base plate.

Table 5 is the Thermal Conductivity calculations of the thin film of SuperTherm only. Specific point of reference is at 100C \ 212 F there are only 3.99 Btu’s per hr\ft2\F absorbed and conducted.

The thermal conductivity of SuperTherm® is the same 4 Btu's whether it is applied to metal, wood, concrete, fibreglass, foam or any other substrate. 4 Btu's is all that is available to transfer per hr\ft2\F.

A heat loss or heat gain of over 350+ Btu’s hr\ft2\F or 4 Btu’s per hr\ft2\F, which would you prefer?

Of course, the optimum application of this technology would be to coat both sides of the substrate so that the heat absorbed by either side would be reduced. In that case the substrate itself could add to the thermal benefit and the thermal benefit would be even greater.

Repel Heat ~ My first choice in terms of preventing thermal transfer, which is in fact the whole point of insulation, would be to repel 100% of the heat and keep 100% of the heat in or 100% of the heat out whichever the desired result. This is what a Ceramic Thermal Barrier Coating does at 90% - 95% and why the optimum application of this technology is to coat both sides of the substrate so that neither side can absorb heat.

If a further reduction in thermal transfer is required or even just desired this is where a hybrid insulation system comes into play. I would use either HPC® Coating Ceramic Insulation Coating or Closed Cell Foam or for the ultimate insulation system a combination of all three.

Block Heat ~ HPC® Coating Ceramic Insulation Coating will block that 5% - 10% and reduce that thermal transfer by an additional 0.063 W/mK. The dead air space contained within the ceramic Cenospheres also provides some thermal storage.

Store Heat ~ For an even greater thermal storage of heat, my first choice of material for that purpose would be Closed Cell Foam. Unlike fibreglass but like Ceramic Coatings, Sprayed Polyurethane Foam provides the additional benefit of an air barrier as well as continuous insulation and is less susceptible to moisture absorptance, particularly Closed Cell Foam. As we know moisture is a thermal conductor not a thermal resistor and has a substantiated negative effect on thermal performance.

Depending on the climatic conditions and the type of occupancy, the mass storage of heat could be beneficial however it could also be detrimental.

An example of a detrimental mass storage of heat would be in an Ice Arena, a Cold Storage facility or even a home in a primarily cooling climate where because of the stored heat, the air conditioner has to keep working even after the outside ambient temperature has cooled down such as at night.

An example of a beneficial application for a hybrid insulation system would be to the interior side of the building envelope in a primarily heating climate in terms of keeping heat in on a metal substrate which unlike concrete (a heat sink) or other building materials has no capacity for the mass storage of those 4 Btu’s. As mentioned above, other insulators to reduce that minimal thermal transfer would be HSC® Coating and Closed Cell Foam. A 25 - 50 mm thickness of Closed Cell Foam coated with 1.25 mm of HSC® Coating would easily block those 4 Btu’s as well as providing for the mass storage of that minimal amount of heat loss. This could be considered one of the optimum hybrid insulation systems for insulating shipping container construction under arctic climate conditions as can be seen in the COLD CLIMATE CONTAINER INSULATION keeping a container home warm at minus -40 C in Quebec, Canada.

So depending on whether the objective is to REPEL Heat, BLOCK Heat or STORE Heat determines which product or products are the best choice.

If the objective is to REPEL heat and keep a surface from absorbing heat initially keeping heat in or out or both, the best choice of product would be a Ceramic Thermal Barrier Coating.

If the objective is to BLOCK heat loss then the best choice of product would be a Ceramic Insulation Coating, such as HPC® Coating, HSC® Coating or HPC-HT® Coating.

If the objective is to STORE heat then the best choice of product would probably be Closed Cell Foam.

Again the ultimate Hybrid Insulation System would be a combination of all three.

The ultimate in energy savings and comfort

The Entire Thermodynamics

Addresses all three forms of thermal transfer being Radiation, Convection and Conduction.

A Ceramic Thermal Barrier Coating Engineered to Repel Heat

on top of a Ceramic Insulation Coating Engineered to Block Heat

over an air trapper heat absorbing insulation Engineered to Store Heat.

*As celebrated theorist Buckminster Fuller concluded: “You never change things by fighting against the existing reality. To change something, build a new model that makes the old model obsolete.”

The ISBU (Intermodal Steel Building Unit) Association (this is the Association for building construction using shipping containers) have reviewed and tested some of the different ceramic coatings.

Here are two Very Important NOTES from a report by the ISBU Association.

Note: Just buying Cenosphere powder DOES NOT make a proper Ceramic paint insulation. It truly requires a special mix of the Cenospheres and certain proportions of other ingredients.

NOTE: Not all manufacturers of Ceramic Coatings and Ceramic Microspheres are using credible formulas and materials.

OUR NOTE: This is why it is so vitally important to review each product's specifications and certifications in general and CERTIFIED THERMAL TESTING in particular.

Here is a link to some excerpts from this arm's length third party ISBU ASSOCIATION REPORT ON CERAMIC COATINGS which contains some excellent information on this technology and is well worth the read.

For further information refer to: Comparison of Thermal Conductivity Measurements of Building Insulation Materials under Various Operating Temperatures

Some of the issues associated with some "air trapper" insulations are addressed in ASHRAE 90.1. For example Table 402R and Table 402S showing the reduced Effectiveness by 63% - 67% with metal trusses and framing respectively.

A Ceramic Thermal Barrier Coating is not affected by metal trusses nor metal framing which is why it is often specified by architects, engineers and building envelope consultants to be applied to steel studs, beams or other metal substrates, etc.. As noted by a PhD in Fluid Mechanics “Typically the studs are not covered by Fibreglass insulation thus allowing a very high conduction path. The heat loss through these studs can be 30-50% depending on the size of the studs and temperature differential between inside and outside. Naturally, the losses are higher in cold climate. Covering these studs with a Ceramic Thermal Barrier Coating will help to cut down the heat losses significantly. Consider the fact the thermal conductivity of steel is up to 46 (W/mK) while it is substantially less for a Ceramic Thermal Barrier Coating. This is 76 times less. So it is very smart to spray a Ceramic Thermal Barrier Coating on these studs and possible on joist and support beams. This is one smart way of preventing big heat losses with a small amount of a Ceramic Thermal Barrier Coating.”.

For an even greater thermal benefit use HSC® Coating Ceramic Insulation Coating (0.07 W/mK) or HPC® Coating Ceramic Insulation Coating (0.063 W/mK).

Sony Engineering in Japan recorded a 13 month ROI (Return On Investment) at their Koda factory. (SONY ENERGY SAVING AWARD). Nissan coated one roof at 2 million square feet. As opposed to R rating thinking which assumes 100% absorptance, they have come to the realization that the most effective means of reducing thermal transfer is by reducing the amount of heat available to transfer. These are smart companies that are saving substantial amounts of money. Over 80 million square feet of a Ceramic Thermal Barrier Coating has been applied in Japan alone.

North America is playing catch up in benefiting from this technology which is ironic considering it is NASA technology to begin with.

There is a HOME AND GARDEN ARTICLE showing the results when the correct ceramic coatings are applied correctly to the exterior and interior of the building envelope in a primarily "cooling climate".

Here are those same ceramic coatings being applied correctly to the interior and exterior of the building envelope in a primarily “heating climate”.

ALBERNI VALLEY MULTIPLEX - MUNICIPALITY OF PORT ALBERNI - greatly reduced the cycles on the compressors resulting in significant energy savings and longer life to the equipment itself.

COLD CLIMATE CONTAINER INSULATION - kept a container home warm at minus –40°C in Quebec, Canada.

HOME BRANDON MANITOBA - increased retained heat in a particularly cold room from +9°C to +25°C

EXCELLENT ICE ADDITION - SURREY, BC - letter from Kirk Fisher P.Eng on the effectiveness even on a pre-engineered steel building which is even more thermally conductive than a tilt up concrete building.

MAPEI WAREHOUSE TILBURY DELTA - still performing as new after 7+ years and still meeting the requirements of ASHRAE 90.1 for Tilt Up Concrete construction.

These are just a few of the numerous satisfied customers and successful Projects world wide.

It is a technology that has proven its value by an informed, intelligent and objective evaluation.

The final point that I would like to make is that unlike certain "air trapper" types of insulation which also trap moisture and lose insulation value when moisture is present, A Ceramic Thermal Barrier Coating does not trap moisture and does not lose insulation value when moisture is present. This is important because moisture is a thermal conductor, not a thermal resistor and has a substantiated negative effect on thermal performance.

For further information refer to: Comparison of Thermal Conductivity Measurements of Building Insulation Materials under Various Operating Temperatures

As per certified ASTM testing, Ceramic Thermal Barrier Coatings are not only a thermal barrier but also a moisture barrier and actually helps prevent condensation and the resulting corrosion or efflorescence. This is just another one of the many benefits that a Ceramic Thermal Barrier Coating brings to TILT UP CONCRETE INSULATION and numerous other applications as per Architectural Specifications "where Ceramic Coatings can be applied to metal, concrete, wood or other substrates where a reduction in thermal transmission is required.".

I would hope that this puts everything into its proper perspective and proves beyond a shadow of a doubt that ceramic coatings are not only a viable option but in fact an excellent technology to provide long-lasting thermal benefits.

A Ceramic Thermal Barrier Coating consists of a specially tuned compound of 4-different ceramics thermo-dynamically tuned to cover the IR, UV, & Visible Light Spectrum, the Thermal Spectrum from -40°C / -40°F to 149°C / 300°F; as well as 68% of the Sound Spectrum!

A Ceramic Thermal Barrier Coating is a Thermal Barrier NOT an Thermal Absorbent! It stops the thermal vibration continuance by its ultra low density. Fiberglass & Foam Insulation are NOT a thermal barrier, they absorb heat until they are saturated then discharge the built up heat into or out of the structure!

Reflective paint vs. A Ceramic Thermal Barrier Coating

Manufacturers in the past have marketed "reflective" paints by making claims that they continuously repel heat. The problem with such claims is that these paints only reflect visual light or short wave radiation, and when they become dirty they stop working completely. Once these claims proved false, all similar coatings were put into the same category and deemed non-viable.

Ceramic Thermal Barrier Coatings were designed and developed with the assistance of NASA, a fact that can be substantiated. The "ceramic compound" blends found to work the best, and are now used in Ceramic Thermal Barrier Coatings. The difference between the technology of "reflective" paints of the past and a Ceramic Thermal Barrier Coating today, is outlined below.

Engineering studies performed by the US Government and independent firms, have concluded that the sun's radiation produces heat from the following sources:

• Ultra Violet (UV) which represents 3% of the heat.

• Visual light or short wave radiation represents 40% of the heat.

• Infrared radiation or long wave represents 57% of the heat.

Once these facts became known, the technology of deflecting and repelling radiation was developed using laboratory testing to identify what methods and elements worked best to address these different types of heat.

A Ceramic Thermal Barrier Coating has the ability to defect and repel all the different radiation waves. A Ceramic Thermal Barrier Coating not only deflects, repels, and emits these waves when first applied, but continue to deflect, repel and emit them after the coating becomes dirty, which happens to all coatings. The ceramics used in Ceramic Thermal Barrier Coatings are chosen from over 3,200 compounds, which were studied and tested in order to prove that they would deflect, repel and emit the different radiation waves the most effectively, producing the following results:

1. Ceramic Thermal Barrier Coatings deflect, repel and emit up to 99% of UV

2. Ceramic Thermal Barrier Coatings deflect, repel and emit up to 92% of Visual Light (short wave)

3. Ceramic Thermal Barrier Coatings deflect, repel and emit up to 99% of Infrared (long wave)

This results in an average of over 96% of heat absorptance deflected, repelled and emitted!

There are few limits to the application possibilities for ceramic coatings. They qualify for anywhere from 2 - 14 points on the LEED (Leadership in Energy and Environmental Design) rating system. They can be used on metal substrates such as mobile homes, livestock barns, grain bins and oil tanks, refrigeration units, trucks etc., to help reduce the HEAT LOAD LOSS by as much as 90 - 95%. This translates into reduced heating cooling needs, less loss of animal life due to escalating ambient temperatures, greater protection for storage contents, greater comfort and increased productivity for personnel and greater life expectancy for the structure itself.

Other substrates likewise, enjoy greatly reduced temperatures, from metal pipes in the industrial field to the concrete surrounding the family swimming pool or anything that people come in contact with.

Additionally, as part of a roofing system, there is no comparison for a Ceramic Thermal Barrier Coating's ability to withstand basic weathering for 20 - 25 years minimum, resisting everything from the normal stresses of expansion contraction, to hail stones, to ponding water, to UV's. Besides normal insulation uses, the combination of RustGrip and a Ceramic Thermal Barrier Coating can survive exposure to the inner workings of an acid incinerator to stop the heat and dripping acids from corroding the steel walls. All this with a USDA-approved, environmentally safe formula that lends itself to possibilities limited only by one's intellect and imagination.

In the US, Hoechst-Celanese Chemical Plant in Houston, Texas had been having problems with keeping their hazardous waste incinerators (operating @ 870°C 1600°F) online due to the heat and dripping unburned acids (during the cooling on shut down). The combination of heat, condensation and unburned acids caused the bottom of the incinerator to totally corrode, forcing complete replacement approximately every 4-6 months. Costs exceeded $.25 million USD per shut down for repairs and lost production which occurred twice per year.

The engineer decided to try using our RustGrip primer and then a Ceramic Thermal Barrier Coating as the top coat at 30 mils DFT to protect the skin of the incinerator from the heat and effects of the condensation and acid. They were applied in February 1992, and to this date, has not required downtime due to corrosion of the skin.

During this time period, approximately $6 million USD has been saved in downtime alone by using the designed protective coating system. A Ceramic Thermal Barrier Coating was tested and approved by Ontario Hydro in Ontario, Canada as the most effective insulator available for their tanks, pipes and buildings. Infrared video was filmed showing the effectiveness of the Ceramic Thermal Barrier Coating's insulation ability over fiberglass, polyester foam, white paint and other types of conventional insulation by visually demonstrating the escape of heat for the protected surface. The Ceramic Thermal Barrier Coating outperformed all other insulation materials.

The blast furnace door at the GVRD waste incinerator was coated with 28 mils DFT of a Ceramic Thermal Barrier Coating to bring the surface temperature down from 150°C 302°F to 70°C 158°F to meet Canadian codes for any surface exposed to human contact. After coating but before full cure a check was made with the computerized control room and the operator immediately cut back the jets due to the increased heat retention again paying for itself in reduced energy consumption. Today we would use HSC®Coating which had not yet been developed and accomplish the same thickness in one coat.

As reported in Rink Magazine, a Ceramic Thermal Barrier Coating is substantially reducing utility costs on various arenas.

As stated by director Dwayne Lowdermilk, National Training Rinks (pre-engineered stress skin metal structure) experienced a

"30% reduction in utility costs; which we sure appreciate".

As noted by Kirk Fisher, P. Eng. , MBA, and the Development Manager for the Lark Group, the application of $30,000 of bulk insulation (foam) at the Excellent Ice facility (pre-engineered stress skin metal structure) located in Kirland, PQ and "the gas and hydro bill didn't change at all". The Ceramic Thermal Barrier Coating was doing all the work and consequently it is specified on the Surrey, BC expansion and all other ice arena developments.

Energy Efficiency Project Analysis for Supermarkets and Arenas

On the Alberni Valley Multiplex (tilt up concrete) a system of Ceramic Thermal Barrier Coatings was applied. In May 2002 the first year audit was completed on this facility and of special interest was the fact that the cycles on the compressors were far below expectations thus resulting in major energy savings as well as longer life for the equipment itself!

At the Bonaire Golf Club the application of a Ceramic Thermal Barrier Coating "saved the purchase of another air conditioner plus all its related energy and maintenance costs, plus we are using the existing two units less and our building is more comfortable. Your product will help Ontario's energy problem."

To date more than 80 million square feet of roofing has been protected in Japan alone using a Ceramic Thermal Barrier Coating for such companies as Canon, Hitachi, Kirin Brewery, Matsushita, Mitsubishi, Sony, Sumitomo, and Nissan to name a few. 2 million square feet of a Ceramic Thermal Barrier Coating was applied to the Nissan Factory Roof in 2004. Sony Engineering group conducted field studies at the Koda factory and determined that the kW usage was reduced from 3,764 kW in May 1994 to 519 kW in May 1995 a reduction of 3,248 kW or 86%. The kW usage in June 1994 was 5,647 kW which was reduced to 1,869 kW in June 1995 which was a reduction of 3,778 kW. This resulted in a payback of 13 months.

As a consequence a Ceramic Thermal Barrier Coating was specified on their new 700,000 square foot facility in Malaysia.

A Ceramic Thermal Barrier Coating was applied on a manufacturing facility in Kansas that was experiencing a great deal of difficulty in cooling various unconditioned buildings of the factory due to variance in size and significant volume. The results were an immediate reduction by 12 degrees Fahrenheit on the lower levels, with an even greater reduction to the attic storage and overhead work zones on the second story. This temperature reduction enabled the facility to utilize simple ceiling fans for cooling during the summer months, and thereby lowering the overall expense of energy.

Ceramic Thermal Barrier Coatings are being applied in numerous areas in the Transportation Industry. They are reducing the fuel consumption on Reefer units by 30%. They are being applied to all the UPS trucks. They are specified by Vancouver Shipyards on all new construction to control condensation such as all the passageways on the new Kootenay Lake Ferry. Ceramic Thermal Barrier Coatings are applied to the interior of Yachts for acoustical insulation as well as to increase comfort. They are also applied to the exterior superstructure of an Oil Tanker for thermal control. On a Casino Ship they were applied as a base coat for moisture impervious insulation.

HPC®Coating was successfully applied at the Gazprom Refinery in Omsk as an insulator in order to maintain internal heat, to reduce the melting threat to the tundra, and to aid in the flow of crude oil through severe winters. Chevron Oil is using HPC®Coating to insulate steam valves some running at 315°C 600°F, which had never been able to be insulated before. Temperatures have been reduced as low as 57°C 135°F. HPC®Coating has seen success in many other industrial Projects.

Years ago, gas was cheaper and no one cared about loss due to evaporation. Now is different. ...we stopped practically 100% of the evaporation due to heat build up on the tank. What evaporation did happen was very little and only the fumes that are associated with gasoline in its liquid state. Now, gas is expensive and this is more of an issue.

Evaporation was not important but the cost of blasting and recoating tanks every 4.5 years was. We could do a RustGrip/Ceramic Thermal Barrier Coating in place of the blast, zinc primer, epoxy middle coat and urethane final coat and save a total of $300,000,000 over a 10 year period covering a 3000 tank field. Stopping evaporation at the time was only going to save $30,000,000 so it was decided to not be important. This $30M was at the pricing back then. It has tripled today. Now, it is important." A Ceramic Thermal Barrier Coating has been specified for various Projects.

Ceramic Thermal Barrier Coatings have have many cost-reducing, profit-enhancing Agricultural benefits. Testing has shown the use of a Ceramic Thermal Barrier Coatings on Farm and Poultry houses greatly lowers inside temperature and humidity levels, which reduces the death-rate of livestock (due to heat stress) by up to 75%. Cooler Farm house temperatures allow for regular feed consumption by livestock, which helps to increase average livestock weight and profits.

Condensation and moisture inside a Farm house quickly deteriorate existing insulation materials, and can be a breeding ground for disease. Ceramic Thermal Barrier Coatings on houses and cold water pipes will eliminate condensation and moisture, extending the life of existing materials and preventing loss of livestock. Use of a Ceramic Thermal Barrier Coating on Bin Feeders also prevents condensation and moisture contamination of the feed, resulting in less feed waste.

A worldwide construction company based in England has specified Ceramic Thermal Barrier Coatings and is applying them around the world on jobs from South Africa to Asia where insulation is needed and the batt-style cannot hold up to the weathering conditions and applications. Numerous Canadian construction companies have also specified Ceramic Thermal Barrier Coatings.